The 2-Row 42mm aluminum core not only increases the fluid capacity of the radiator, but also improves the cores ability to dissipate heat. CSF?s Exclusive B-Tube Technology increases the heat transfer by approximately 15% over regular oval welded tubes. In addition, the super-efficient multi-louvered fins maximize airflow through the core for the best possible performance. Efficiency is key in off-roading as speeds tend to be lower overall so you end up relying on the fans to move most of the air over the radiator.

While the factory fans do a decent job pulling air through the radiator core, it is still less airflow than you?d typically see in city driving. A larger and more efficient core will keep your engine temps in check and keep your engine running strong. Additionally, the end tanks are made from high grade aluminum and TIG welded to the core for extra strength.

In contrast, the OEM crimped onto plastic end tank design is much weaker and creates a weak point where failure is more likely. Because the CSF radiator is designed as a true plug-and-play drop-in fit application, installation requires absolutely no modifications, trimming, or cutting.

CSF Racing Radiators

CSF racing radiators feature the most advanced and efficient radiator cores in the industry. Offered for both vehicle-specific and universal applications, they use innovative tube and fin technologies with industry-leading testing methods to maximize airflow and heat dissipation.

Specially engineered tubes in the shape of a "B" are carefully formed and then brazed over the seam. CSF is able to use thinner and lighter aluminum because this design is stronger than normal welded "O" shape tubes. With the inlet in the middle of a seam-brazed tube, the surface area of the tubes is increased approximately 15 percent over regular tubes. With CSF's B-tubes you get dual liquid laminar flow and the efficiency of two smaller tubes vs. one large tube in the same space.

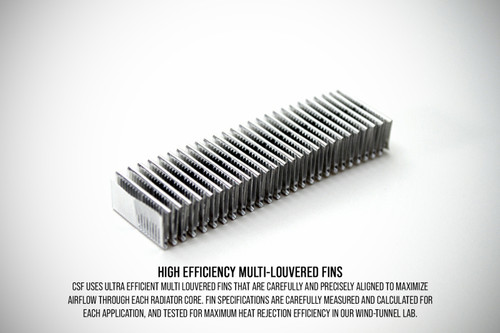

High-efficiency, multi-louvered fins are precisely aligned to maximize airflow through each radiator core. Fin specifications are carefully measured and calculated for each application, and tested for maximum heat rejection efficiency in CSF's wind-tunnel lab.

CSF offers two all-aluminum end-tank designs to match any style and performance needs. CSF 7000 Series racing radiators have OE-style radial tanks that are flat, rounded, and welded together. Perfect for the customer who likes the sleek and smooth look, and wants to display the intricate welding.

CSF deep-drawn end tanks are stamped to the same geometry of OE plastic end tanks. The only high performance manufacture to feature this advanced radiator technology; CSF deep-drawn end tanks feature less welding, and are generally considered the strongest tanks in the industry.

Additional features of CSF racing radiators include:

* Finished with CSF's Show-Stopper mirror polish process

* CAD/CAM designed

* Racing-style aluminum drain plug

* Brazed in a controlled atmosphere brazing (CAB) furnace—the preferred process for aluminum

* ISO 9001/9002 certification

* Military-grade (special clad) aluminum used for tubes, fins, and headers

* Plates and side brackets meet JIS 3003 specifications

* Privately owned factories with full in-house tool rooms

* CNC-machined fittings

* TIG welded